A few years ago, I was able to make a sale to a Plant Engineer who told me that each year he was responsible for saving the company xxx amount of money and that year my project with him checked that off his list. From that experience, I realized that if you can get "ROI- Return on Investment" on your side, the sales pitch becomes a less necessary step.

I recently outlined the "Real Cost of a Vacuum Pump Oil Change" (CLICK TO READ ARTICLE) where I was able to detail the total cost in securing, changing and disposing vacuum oil. Oil is certainly one piece of the cost puzzle but may not provide that total ROI bump to start replacing vacuum pumps.

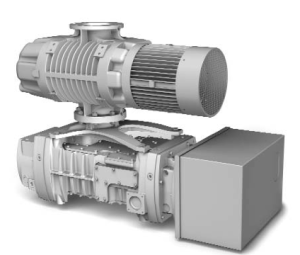

One other piece of that cost savings puzzle is in the electricity cost to generate that vacuum environment in your system or tool. If you enjoy reading dry pump literature, you will find one of the bullet points in most all literature to be "costs savings in electricity". But to know the true reality is hard to determine.

In research to answer this question, turns out the Department of Energy-Lawrence Livermore Labs has used tax dollars to research the validity of the claim. If you wish to review their entire report here is the link but I will highlight their research:

High efficiency dry pumps available today can provide savings of up to 60% over older conventional oil sealed vacuum pumps

Frequency control on modern pumps allow for turn down during process times that do not require full pumping performance . This idle/controlled mode results in energy savings.

High efficiency dry vacuum pumps produce less heat that results in less air conditioning needed and a reduction in cooling water costs.

Lower noise levels and smaller footprint in these dry pumps allow for closer integration to the tool or chamber resulting in less evacuation time.

Finally, lower power requirements allow for smaller electrical infrastructure in new plants.

In summary, if you can isolate the electricity cost of your present older vacuum pumps, the 50-60% savings in replacing older pumps with modern energy saving designs, can be documented with research by the Department of Energy. Adding in the factors like the cost of oil changes only add to that savings.

The ROI in vacuum pump technology may be closer than you think.

For more analysis on developing the ROI for your pumps, check out our Dry Pump ROI Calculator where you get data for your pumps and pump systems.

At Schoonover, we represent major vacuum equipment companies in technical sales and support. We also have our own Apex Vacuum Brand of high vacuum equipment. For more information visit us at www.schoonoverinc.com and www.apexvacuum.com.