Applications

Vacuum Metalizing

Optical Thin Film Coating

Anti-Reflective Lens Coating

Semiconductor Vacuum Coating

Paralyene Coating

In-Line Vacuum Coating

Vacuum Web Coating

Diffusion Pump Trapping of Oil

Closed Loop Foreline Traps

MegaCold Water Vapor Cryopumps

The MegaCold Water Vapor Cryopump provides the most cost effective solution for vacuum pumping water vapor in a vacuum system, dramatically reducing pump down times and significantly improve product quality. In production applications, this means more cycles per day. In most cases 50- 100% throughput improvements are achievable, cutting pump down times in half. The MegaCold works on the principle of Meissner trapping: water vapour is captured by condensing onto a cryogenically cooled surface (a cryocoil) that is placed inside the vacuum chamber. With this design/equipment pumping is not limited by the size of pumping ports.

The MegaCold is controlled by an industry standard PLC with a touchscreen local interface. The MegaCold also has a full set of remote options available. The equipment is available in single & dual output cooling circuits options, giving independent control over a cryocoil and baffle..

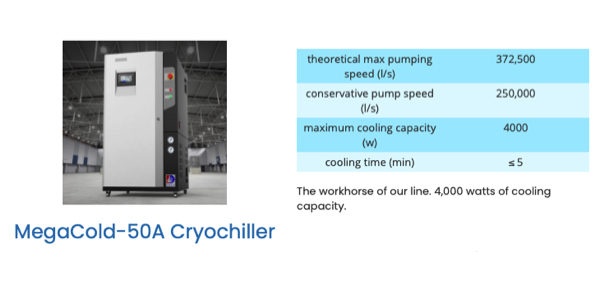

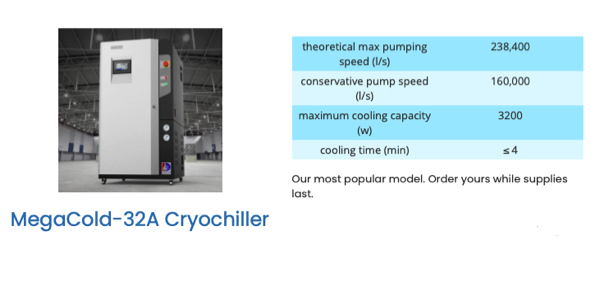

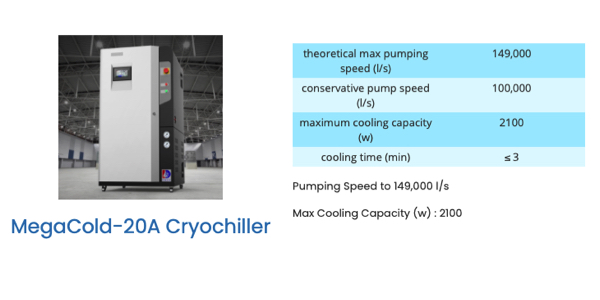

Available models:

MegaCold 12A CryoPump- Vacuum Pumping Capability 60,000-89,400 l/s -Heat Load Capacity 1500 Watts

MegaCold 20A CryoPump- Vacuum Pumping Capability 100,000-149,000 l/s -Heat Load Capacity 2100 Watts

MegaCold 32A CryoPump- Vacuum Pumping Capability 160,000-238,400 l/s -Heat Load Capacity 3200 Watts

MegaCold 50A CryoPump- Vacuum Pumping Capability 250,000-372,500 l/s -Heat Load Capacity 4000 Watts

Advantages/Benefits Water Vapor Cryopumps

- 1. In chamber pumping speed of water vapor from 60,000 l/s to 350,000 l/s. Using the MegaCold units, the trapping is done by the coils inside the chamber, thus flange size is not a limiting pumping speed factor.

- 2. MegaCold systems have regenerative heating capability, thus regeneration is quick, easy and casually be accomplished during the loading of product.

- 3. Addition of a MegaCold can cut the pump down time to base vacuum by 50%.

- 4. Since 90% of outgassing in the high vacuum regime is water vapor, addition of a cryopump chiller is the most effective use of vacuum pump dollars.

Competitor Model Matrix- Which MegaCool Model to Replace Current Water Vapor Cryopump?

MegaCool 12A

Telemark 1800

Brooks Polycold PFC 552HC

MegaCool 20A

Telemark 1800

Polycold PFC 672HC

MegaCool 32A

Telemark 3000

Brooks Polycold PFC 672HC

Brooks Polycold PFC 1102HC

MegaCool 50A

Telemark 3600

Brooks Polycold PFC 1102HC

Brooks MaxCool

MegaCold Service

|

USA, Canada & South America |

MegaCold Systems Inc 1845 Piner Rd, Santa Rosa CA 95403 USA Tel: +1 707 578 6342 |

Needing service for your Polycolds or Telemark?

Polycold & Telemark Service

We provide:

Field Service

Factory Rebuilds (Our Factory in CA)

Refrigerant Charges

Spare Parts

Cryocoil Fabrication & Design

Cryogenic Trap Feedthroughs

Accessories Available

Cryocoil

The cryocoil will be designed to fit the specific vacuum chamber. We can design and fabricate a coil for a certain area of the chamber wall. This is important for existing chamber systems. Coil design is based on information you supply, or you may choose to design and build your own cryocoil. Typical cryocoils have helical, spiral, serpentine or other simple shapes.

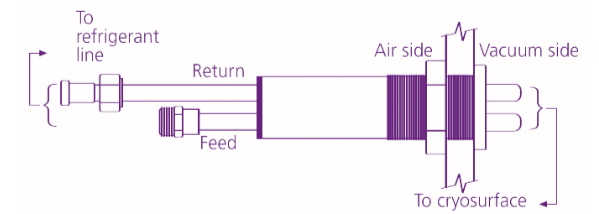

Feedthrough

The standard cryogenic feedthrough provides isolation between the outside atmosphere and the vacuum in the chamber between the feed/return tubes and the O-ring seal. The dual pass feedthrough requires a two-inch diameter hole in the vacuum chamber.

Refrigerant Line

A standard refrigerant line set consists of a copper feed & return line, each with stainless steel couplings on both ends for connection to the MegaCold unit and to the feedthrough. The black outer foam is to reduce/prevent frost build-up on the coil. Vacuum insulated lines are available if required due to long runs. Standard refrigerant line length is 8-10ft.