DIJ Diffusion Pumps

Applications

PVD Vacuum Coating

Vacuum Furnaces

Metallurgy

Tool Coating

Vacuum Metalization

Electron Beam Welding

Optical Coating

Anti-Reflective Coating

Improved Design - DIJ Advantage

- High Vacuum Pumping Speed

- High fore vacuum tolerance

- 30% Better Power Efficiency

- Fast Heater Replacement

- ECO Energy Controller w/2 yr. ROI

- CE Compliant Electronics

Five Stage Design

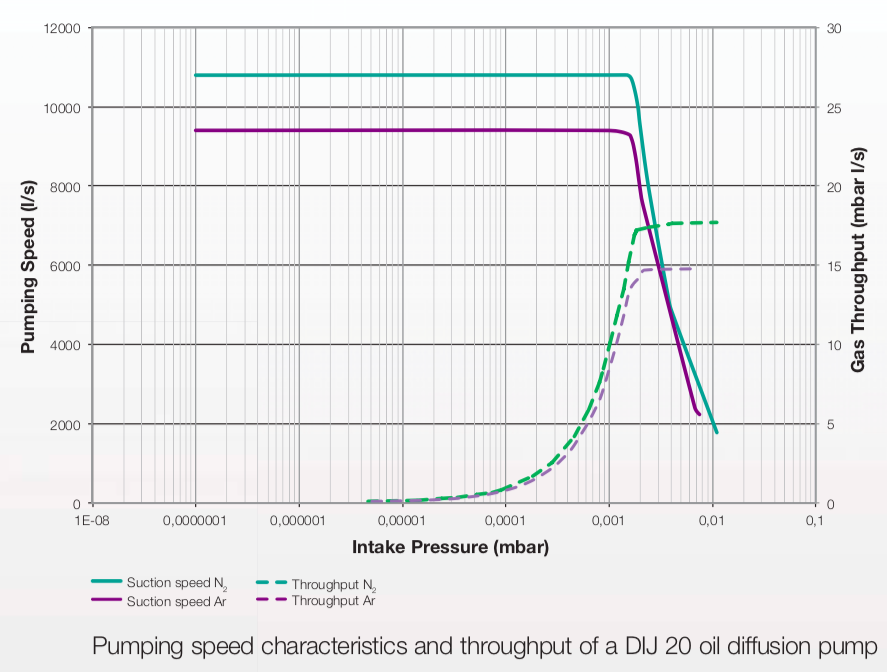

The DIJ five stage design incorporates four diffusion stage along with an additional ejector stage which gives the Leybold DIJ Diffusion Pump a higher suction pump speed. This 5 stage design results in quicker pump down to base pressure. Vacuum stable throughput at pressures 10-3 mbar.

Innovative Heater Cartridge Design

In-oil cartridge heater design with a large heating surface that optimizes energy transfer into the oil. Similarly, monitoring of the oil temperature ensures the heaters are not subject to an overheat condition. This constant monitoring also ensures longer element life. In addition, flanged heaters make change-out the fastest in its class.

Unique Baffle Design

Cold cap design is provided at the inlet to minimize oil back streaming into the vacuum chamber. The fore-line baffle is also designed to reduce oil losses for more economical operation.

Electrical Connection Models

Three different variations for each individual application.

1. Basic – simplified OEM connection with male plug

2. Standard – with circuit breaker box

3. ECO version with switchbox and energy control unit

How the DIJ Diffusion Pumps Meets Your Vacuum Pumping Challenges

Lower Running Costs

During active pump down, power is supplied at 100% but is dropped down as low as 30% during process to reduce energy consumption

Change Oil Only When Really Needed

The ECO Controller monitors oil health to get away from changing oil due to run hours only

Change Heater Elements In-Situ

Flanged heater design provides quick change out to promote higher production up time

Five Stage Design

Faster pump down times to promote more runs and higher production

Visual Monitoring of Process Parameters

Digital output of operating oil temperature with options for USB or Ethernet Communications

DIJ Maintenance Benefits

- No Wear Parts

- Flanged Cartridge Heaters for Fast Change-Out

- ECO Controller to Monitor When Oil Needs Changing

- Increased Lifetime of Cartridge Heaters

DIJ Application Benefits

- Five Stage Design for Higher Pumping Speed

- Simple Operation

- High Forevacuum Tolerance

- High and stable throughput at pressures >10-3 mbar