VARODRY Dry Screw Vacuum Pump For Industry

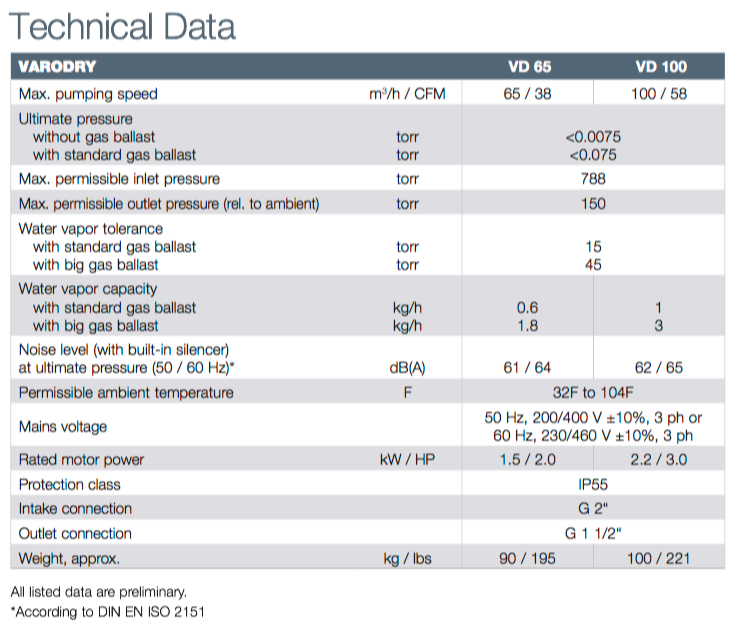

Models - 65 & 100 m3/hr Pumping Speed

VARODRY Dry Vacuum Screw Vacuum Pump

Applications

Well-suited for use in all applications which require a dry and clean vacuum:

Electron beam welding

Lasers

Leak detection systems

Accelerators / synchrotrons

Transformer Drying

Load lock / transfer chambers

Lamp manufacturing

Brake Filling

Refrigeration System Pumping

Easy Efficient & Reliable Dry Vacuum Pumping

- No oil, non-contacting screw vacuum technology

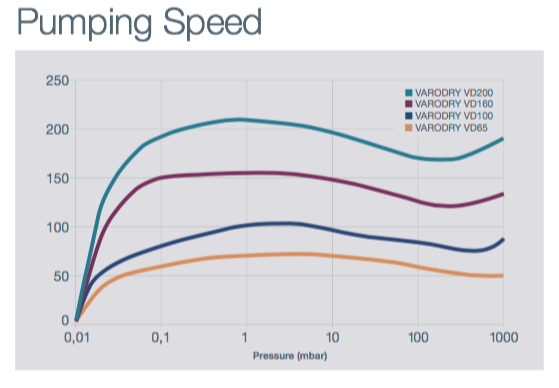

- High suction speed over the complete operational pressure range

- High water vapor tolerance

- Fast cycle times for rated pumping speed

- Minimal noise level during normal operation

- Easy to maintain long life belt driven pump technology

- Low operational cost air cooled design

-

Lowest power demand in its class

Replace Oil Sealed Vacuum Pumps

VARODRY Dry Vacuum Pumps are designed to replace older oil sealed vacuum pumps in industrial applications. The disadvantage of oil sealed vacuum pumps is that the water vapor and other contaminants from the process typically end p in the oil. Furthermore, Oil degradation can lead to excessive pump wear which means the pump must be rebuilt more frequently or lose vacuum capability.

Pump Design

Non-Contacting Screw Technology with milled twin rotors to create vacuum with no particulate generation. To keep the design simple, the VARODRY screws are belt driven with a field serviceable belt. Ample air cooling eliminates utility costs and energy consumption. As a result, the VARODRY has a very low cost of operation compared to oil sealed vacuum pumps.

VARODRY Application Benefits

- Excellent Pumping Speed over Entire Pressure Range

- Handles Fine Dust Particles without Pump Wear

- High Water Vapor Tolerance

- Can Handle Droplets or Liquid Slugs

- Robust & Designed for Industrial Applications

- Air Cooled Pump-No Water Cooling Needed

VARODRY Maintenance Benefits

- Drive Belt Exchange is 1 year or More

- Belt Exchange Takes 30 Minutes or Less

- Bearing Change is 3 Years or More

- Field Serviceable by Leybold Field Technicians

How the VARODRY Meets Your Vacuum Pumping Challenges

Repeated and Fast Cycling

The VARODRY provides quick pump down. In addition, it tolerates atmospheric pressure shocks and repeated evacuation cycles.

Reactive Gas Handling

Often vapors (ex. hydrocarbons) react inside hot dry pumps and cause build-up on internal screws which can cause the pump to seize. In the VARODRY, the temperatures are not high enough to cause this issue.

Water Vapor Handling

Due to its optimized temperature profile & integrated gas-ballast, the VARODRY offers a high water vapor tolerance, avoiding internal condensation and corrosion.

Liquid Handling

Liquid HandlingThe VARODRY can handle liquid droplets or slugs as these flow freely through and outside the pump during normal operation.

Dust / Particle Handling

The pumps screw design optimizes the pump's ability to handle fine, dry dust particles without wear. In addition, a wide range of dust filters are available.