Stainless Steel Chambers- High Vacuum & UHV

In business since 1967, Sharon Vacuum specializes in high vacuum chambers and ultra-high vacuum chambers for high vacuum coating processes and research and development. Box chambers are built to a maximum size of 36" x 48", stainless steel bell jars to 40" in diameter. All vacuum chambers are cleaned for high vacuum service and helium mass spectrometer leak tested following fabrication.

Vacuum Chambers from Rough Vacuum to Ultra-High Vacuum (UHV)

Sharon Vacuum has a 40 year history of providing high vacuum and ultra-high (UHV) vacuum chambers to the leading research and development institutions and vacuum coating OEM's. Sharon Vacuum specializes in custom designs meeting customer specifications. Various types of finishes are available from a bead blast to electro-polished.

Chamber applications include surface science physics, photonics research, high magnetic field environments, chemical vapor deposition, physical vapor deposition and many others.

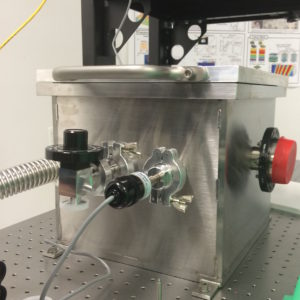

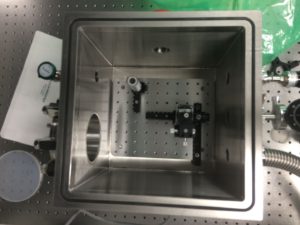

University of Central Florida

Recent High Vacuum Chamber from Sharon Vacuum

Pictures from recent chamber supplied by Schoonover to the University of Central Florida Nanotechnology Center. This chamber is being used in optical nano science experiments. The interior of the chamber has a bread board in the bottom to allow for connection of the vacuum viewports to the chamber. Pumping of the chamber is from a Leybold Turbolab 80 High Vacuum Turbo Pump System, also provided by Schoonover.

Chamber Quotation Form

Complete the form to receive a quotation for your chamber design. Time frame to quote is 2-3 business days.

_____________________________________________________________________________________________________________________________________________________________