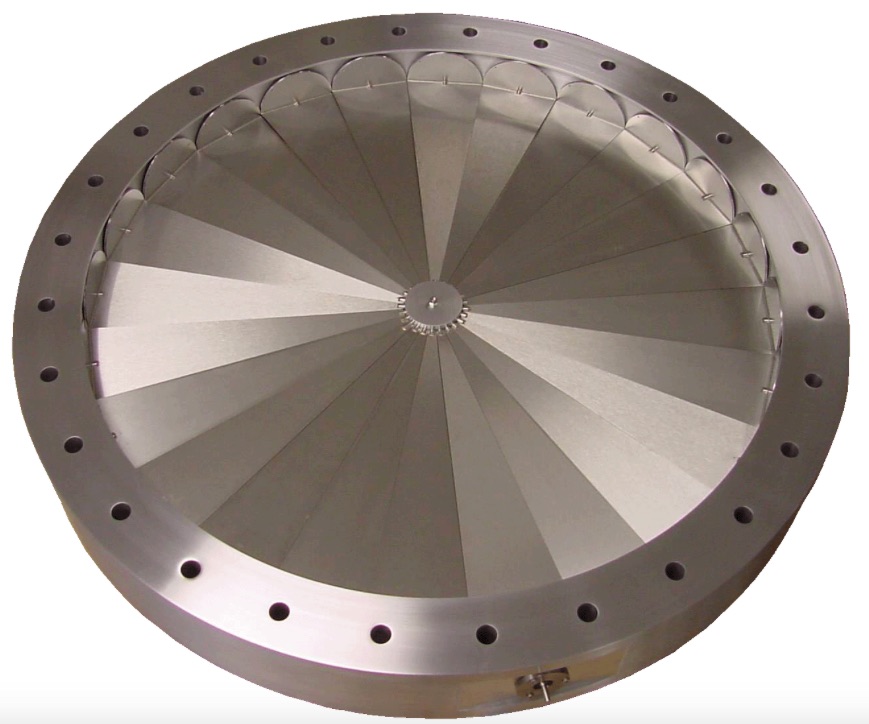

Vacuum Pressure Control

Throttle Valve (ISO,CF & ASA)

Control of the vacuum pressure is essential in applications such as vacuum coating and etch processes. The Meivac vacuum pressure throttle valve is a downstream valve, meaning that the operation of the valve is positioned over the vacuum pump to regulate the conductance of the pump.

The counter-rotating vane set allows for linear control across the entire operating range of the valve. In the open position the VQ throttle valve vanes offer a low amount of conductance restriction of the pumping path during critical pump down operations. The low profile design of the Meivac provides the most compact pump stack height for any valve and high vacuum pump combo.

How the Meivac Throttle Valve Works

A high vacuum pump normally operates at a lower pressure than optimal vacuum coating applications. Thus, a way to increase the pressure is required. Trolling the gas in the vacuum coating chamber provides a differential pressure to be created across the valve, allowing the pump to operate at high vacuum, while the process chamber can operate at optimal process pressures. To provide linear control, the vanes on the Meivac valve are counter-rotated, providing optimal pressure control over the range of operation. In the open position, the throttling valve does not restrict the pumping path, thus a very low conductance loss to pumping operations.

For automated pressure control, the valve is operated via a Servomotor to position the valve rotor to provide upstream control of the pressure in the chamber. Pressure reference is a set point from an external capacitance diaphragm gauge mounted on the vacuum chamber.