Sparkler Horizontal Plate Filter

The cake filtration process is more economical to operate than bag or cartridge filters when filter aids are required to meet clarity specifications and achieve process flow rates. The capability to wash and dry the filter cake maximizes product recovery and minimizes operator exposure.

For high process flow rates, horizontal plate filters have the highest surface area to tank volume ratio of any filter design. Intermittent operation is possible and cake stability is assured with the plates in the horizontal position. Continuous operation is possible with two filters, one online and one off-line for cleaning and standby.

Sparkler Filters manufactures a variety of Horizontal Plate Filters that are used for making sparkling clear products in chemical, food, beverage, pharmaceutical and other industrial plants. Contact Schoonover, Inc. for assistance in choosing the filter that best fits your filtration needs.

(SHPF) Standard Horizontal Plate Filter

Sizes:

Filter Septum:

Std. Capacity Range:

Cake Discharge:

Additional Notes:

14″, 18″ and 33″ Diameter

Paper, Cloth or Non- wovens

Filter Area: 3.5 -158 ft2

Cake Volume: 0.1 – 14 ft3

Manual, Dry Cake

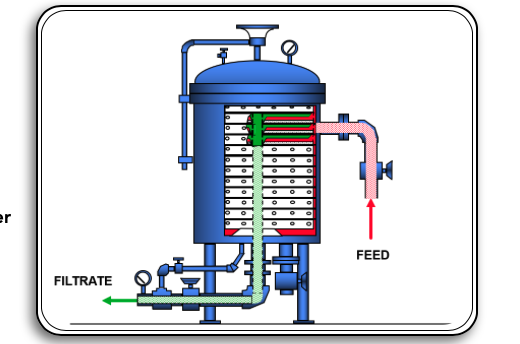

The HPF horizontal plate filter has a vertical tank with horizontal stacking plates and tie rod compression. Flow is into the tank, across the filter plates, through the media, and down the center column with bottom filtrate outlet. It is a general purpose filter for up to 5% solids, tolerates intermittent flow, and has a wide selection of septum (media) materials. This filter can adapt to almost any process with precoat and bodyfeed.

Reverse Flow Horizontal Plate Filter

Sizes:

Filter Septum:

Std. Capacity Range:

Cake Discharge:

Additional Notes:

18″ and 33″ Diameter

Paper, Cloth or Non- wovens

Filter Area: 6.2 -153 ft2

Cake Volume: 0.62 – 12.76 ft3

Manual, Dry Cake

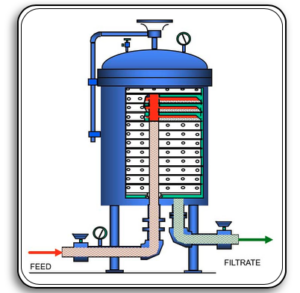

The Revere Flow horizontal plate filter has a vertical tank with horizontal stacking plates and tie rod compression.Unlike the Sparkler Standard Horizontal Plate Filter, flow enters the filter from the bottom of the filter, through the cartridge and out the upper portion of the filter tank. This feature keeps all the filtered particulate inside the tank cartridge (zero-heel), giving the user a clean sanitary operation and cleaning.

All target filtrate remains within the cartridge, leaving the vessel perfectly clean from one cycle to the next. This means the vessel, itself, requires no cleaning between cycles. The cartridge is designed for clean-ability.

VR and V Horizontal Plate Filter

Sizes:

Filter Septum:

Std. Capacity Range:

Cake Discharge:

Additional Notes:

12", 17" and 32" Diameter

Paper, Cloth or Wire Mesh

Filter Area: 4.7 - 351 ft2

Cake Volume: 0.07 - 8.2 ft3

Manual, Dry Cake

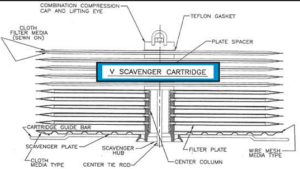

The VR filter is a horizontal plate filter design for using paper media on the top and bottom of the plate. This trap filter design gives double the surface area for high flow rates with low solids. If flow stops, the cake can drop from the bottom of the filter plate. The V filter has a dual V design horizontal plate with either welded wire mesh media or cloth bags to cover both sides of the plate. Both the V and the VR Filter are trap filters for polishing. They have high surface area, low cake volume and are used for low solids content removal.

WO and WOT Horizontal Plate Filter

Sizes:

Filter Septum:

Std. Capacity Range:

Cake Discharge:

Additional Notes:

18" and 33" Diameter

Cloth, Non- wovens or Wire Mesh

Filter Area: 3 - 128 ft2

Cake Volume: 0.3 - 18 ft3

Manual Wash-off, Automatic with Internal Sluice

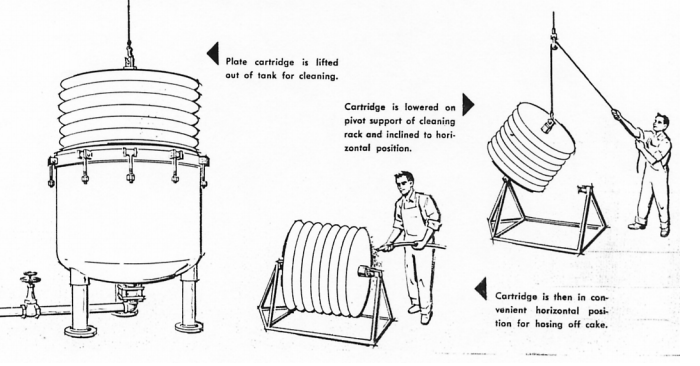

The WO is a wash-off horizontal plate filter where the filter plates pull as a unit from the tank and do not require disassembly for hosing off the cake outside the tank. Either welded wire mesh or cloth bag media is used. The WOT or wash-off tilt filter has an internal sluice header and tilts from the vertical tank position to the horizontal for washing-off cake without opening the tank. Both the WO and the WOT Filters are for processes where cloth or wire mesh septum is appropriate. Precoating is required but there is no disassembly of plate bundle for cake removal. Bundle is simply removed from tank and washed off.

HRC and HRS Horizontal Plate Filter

Sizes:

Filter Septum:

Std. Capacity Range:

Cake Discharge:

Additional Notes:

Range depending on filter location

Wire Mesh or Cloth

Filter Area: 62 - 310 ft2

Cake Volume: 10 - 52 ft3

Automatic Dry Cake, Wet Cake with HRS

The HRC is a horizontal plate filter with a rotating plate carriage in a horizontal tank. The plates are horizontal for filtration and rotate to the vertical position for automatic dry cake discharge with a vibrator and internal screw conveyor. The HRS is a horizontal plate filter with a rotating plate carriage and an internal sluice header for wet cake discharge through a drain. The HRS filter does not have an internal screw conveyor, so the filter tank volume is smaller. Both the HRC and the HRS provide stability of horizontal plate during filtration. Plates rotate to vertical position for cake discharge and requires clean precoat.