Industrial Dry Pumps

SCREWLINE SP250 & SP630

DRYVAC DV630 & DV1200

LEYVAC LV80 LV140 & LV250

CLAWVAC

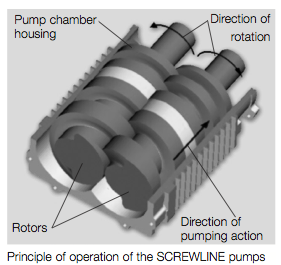

Screwline Industrial Dry Pump

SCREWLINE Vacuum Pumps for industrial applications are dry compressing pumps. The pumping chamber of the pump is formed by two synchronised positive deplacement rotors. SCREWLINE Pumps are air cooled from the outside. The SCREWLINE was developed as the low maintenance industrial dry pump.

For standard applications, no purge gas is required. However, should the application require a purge gas, then one can be provided.

Because of the cantilevered bearing arrangement for the rotors, a potential source of failure (i.e. a bearing on the intake side) is eliminated. No lubricants from the bearings can enter into the vacuum side of the pump, and any aggressive gases in the vacuum process do not affect the bearings for the cantilevered rotors.

Another benefit of the cantilevered bearing arrangement is easy accessibility for cleaning the pump chamber. This innovative design feature allows the removal of the pump housing without time-consuming and costly disassembly of the bearings. Therefore on-site cleaning of all surfaces in contact with the medium is possible. In particular, if the processes involved considerable amounts of contaminants this is a significant advantage which ensures a long uptime.

Applications:

- Industrial furnaces

- Coating technology

- Load lock chambers

- Metallurgical systems

- Packaging technology

- Drying processes

- Degassing

- Research and development

- Lamps and tubes manufacture

- Automotive industry

- Packaging industry

- Space simulation

- Electrical engineering

- Energy research

SCREWLINE Industrial Vacuum Dry Pumps

SCREWLINE with WSU Blower Attached

SCREWLINE SP250

Pumping Speed: 194cfm

Cooling: Air

Inlet Flange: ISO63

Ult. Pressure (Torr) 3.8 x 10-3

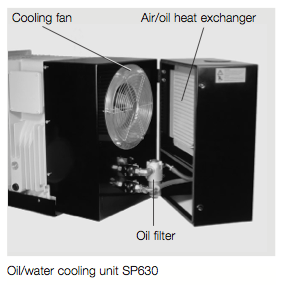

SCREWLINE SP630

Pumping Speed: 371 CFM

Cooling: Air

Inlet Flange: ISO100

Ult. Pressure (Torr) 7.5 x 10-3

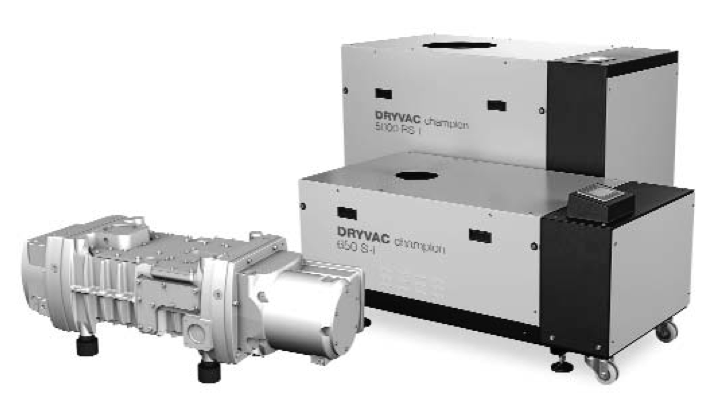

DRYVAC Industrial Dry Pump

The DRYVAC delivers optimum pumping speed with an ultimate pressure at or below 75 mtorr. DRYVAC Vacuum Pumps are suited for short cycle operation (load locks, for example) or for the evacuation of large vacuum chambers.

The DRYVAC champion models offer reliability in applications utilizing harsh processes. They have been optimized for pumping in photovoltaic and flat screen production processes. The DRYVAC champion offers a high pumping speed for hydrogen and an integrated purge gas system that is insensitive to dust.

The customer benefits offered by the DRYVAC are it's compact design, low-profile to operate in tight footprints and the option of easy-to-build horizontally arranged pump systems.

Benefits/Advantages

- Water cooled

- Hermetically sealed screw and Roots pumps, static seals only towards the outside

- Simple mechanical and electrical integration

- Integrated protection function via temperature, exhaust pressure and current consumption

- Small footprint

- Low energy consumption due to optimized rotor geometry and innovative rotor design

- Wide voltage and frequency range: 380-480 V, 50/60 Hz

- UL listed materials (NRTL certification pending)

- RoHS compliant

DRYVAC with silencer panels and without

DRYVAC Industrial Dry Pump

DRYVAC 450

Pumping Speed: 265cfm

Cooling: Water

Inlet Flange: ISO100

Ult. Pressure (Torr) ≤ 5 x 10-3 mbar

DRYVAC 650

Pumping Speed: 383cfm

Cooling: Water

Inlet Flange: ISO100

Ult. Pressure (Torr) ≤ 5 x 10-3 mbar

LEYVAC Industrial Dry Pumps

Our new LEYVAC dry vacuum pumps provide power combined with high performance. The two sizes of the LEYVAC Dry Pumps fit nicely in the Leybold dry pump portfolio. The LV 80, LV 80C, LV 140 and LV 140C provide dry pump options to replace a number of wet pump applications with new technically proficient dry pumps. The LEYVAC Dry Pumps were designed for industrial processes and coating applications.

LEYVAC pumps and system combinations provide rugged, reliable and durable dry pumping, ready to operate in harsh process requirements.

The design of the LEYVAC Dry Pumps is based on the proven RUVAC and DRYVAC technology that has proven for years to provide the highest level of service. Range of the LEYVAC is atmosphere to process pressures in the low millitorr range. The LEYVAC pumps can be integrated with Leybold Roots Blowers for enhanced pumping speed in production applications.

Applications

- Industrial furnaces

- Degassing

- Charging

- Casting

- Drying processes in general - Freeze drying

- Packaging

- CVD coating

- Plasma coating - Glass coating

- Web coating

- CVD/PECVD

- Crystal pulling and casting

LEYVAC Dry Pump with Roots (Adaptor in red circle)

LEYVAC Industrial Dry Pump

LEYVAC LV 80

Pumping Speed: 55.9cfm

Cooling: Water

Inlet Flange: ISO63

Ult. Pressure ≤1 x 10-2 mbar

LEYVAC 80C versions with silencer housing

LEYVAC 140

Pumping Speed: 85.3cfm

Cooling: Water

Inlet Flange: ISO63

Ult. Pressure ≤ 1 x 10-2 mbar

LEYVAC 140C versions with silencer housing

LEYVAC 250

Pumping Speed: 147cfm

Cooling: Water

Inlet Flange: ISO63

Ult. Pressure ≤ 1 x 10-2 mbar

LEYVAC 250C versions with silencer housing