MAK Sputter Deposition Sources

Meivac is a leading provider planar magentron sputter deposition sources. The MAK Sputter Sources range from 1.3" to 6" diameter and can provide vertical, horizontal, flexmount and flange mount configurations.

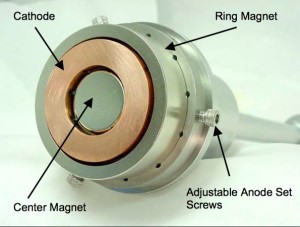

One key feature of the MAK Sputter Sources is the ease of target change-out. The target is retained by the magnet structure by a simple keeper. Target change-out can be accomplished without having to disassemble the MAK Sputter Source. Other important benefits/advantages of the MAK Sputter Source include.

- The cooling water channel is not part of the high voltage path

- Sputter source magnets are not in the cooling water channel

- No water to vacuum seals

- Target requires no clamping or bonding to the cathode

- Operates in DC or RF modes

- Adjustable anode that improves uniformity to prevent build-up and shadowing

- Both high vacuum and ultra-high vacuum designs

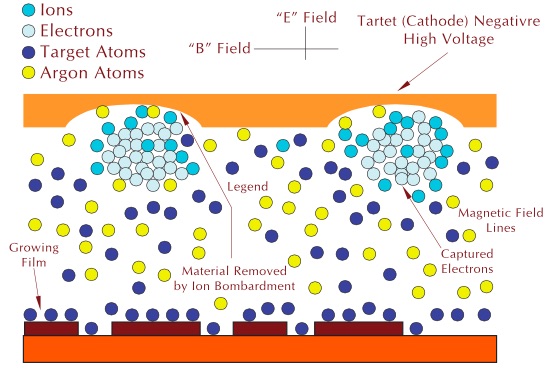

Principles of Vacuum Sputtering

Sputter Deposition in a vacuum chamber typically has a substrate (item to be coated) on one side of the chamber, and a sputter magnetron target opposite the substrate. The vacuum chamber is evacuated and the chamber is backfilled (usually argon). Gas is ionized with a positive charge to create a plasma. Resulting ions are attracted to the negatively charged target. As the large argon ions hit the target material, the atoms/molecules of the target material are physically removed from the target. Due to the close proximity of the substrate, the removed material is sputtered material and lands on the substrate with enough energy to create a thin film, one monolayer at a time.

Cross Section of a Planar Magentron